Welcome 2026: A Year of Purpose, Partnership, and Progress

Happy new year! As we enter 2026, PROLANGH extends its sincere greetings to our partners and clients worldwide. The new year is a moment of

Home » Insights & News

Welcome to "Insights & News," your go-to resource for the latest in hardware manufacturing. Explore industry trends, innovations, and expert insights designed to inform and inspire. Stay ahead in your field with our curated, up-to-date content.

Happy new year! As we enter 2026, PROLANGH extends its sincere greetings to our partners and clients worldwide. The new year is a moment of

Happy New Year! As we step into the first day of 2025, the team at PROLANGH would like to extend our warmest New Year greetings

The escalating trade tensions between the United States and China have led to significant changes in the global trade landscape. One of the most impactful

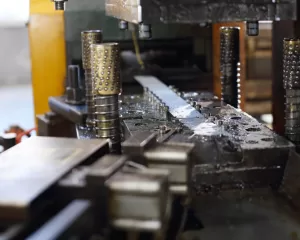

In the realm of metal fabrication, the evolution of technology and techniques has continually paved the way for more efficient, precise, and cost-effective manufacturing processes. Among these advancements, progressive die stamping stands out as a significant leap forward, especially when compared to traditional single punch press operations. This article delves into the fundamental differences and advantages of progressive die stamping, highlighting why it is often the preferred choice for high-volume, complex metal part production.

Happy New Year! As the first day of 2024 unfolds, we at PROLANGH want to take a moment to extend our heartfelt New Year greetings to all of our valued clients and future partners.

In the realm of hardware manufacturing, the significance of quality control cannot be overstated. It is a pivotal aspect that not only reflects the integrity of a brand but also determines its success in a competitive market. At PROLANGH, our commitment to quality control is unwavering, and we have established a comprehensive system to ensure every product we manufacture meets the highest standards.

In today's world, where security is a top priority, it's crucial to have a locking system you can rely on. That's where our KM 3 Star Cylinder comes into play. This lock isn't just another addition to the market; it's a leap forward in securing your peace of mind.

Happy new year! As we enter 2026, PROLANGH extends its sincere greetings to our partners and clients worldwide. The new year is a moment of clarity and renewed direction. It invites reflection on the trust we have built and anticipation for the opportunities ahead. We value the confidence you place in PROLANGH and the long-term relationships that continue to shape our shared progress. In the year ahead, we look forward to deepening collaboration, pursuing sustainable growth, and moving forward with purpose in a dynamic global landscape. We thank you for being part of our journey and wish you a refined, successful, and prosperous New Year. Warm regards PROLANGH Team

Happy New Year! As we step into the first day of 2025, the team at PROLANGH would like to extend our warmest New Year greetings to all our valued clients and partners. The arrival of a new year signifies a time of renewal, optimism, and boundless potential. It’s an opportunity to reflect on our collective accomplishments and envision the goals we aspire to achieve together. We are deeply appreciative of your trust and collaboration, which have been the cornerstone of our progress and success. In 2025, we are committed to forging stronger partnerships, fostering innovation, and achieving new milestones. This year, we will continue to deliver exceptional solutions and exceed

The escalating trade tensions between the United States and China have led to significant changes in the global trade landscape. One of the most impactful measures has been the imposition of sanctions and increased export tariffs by the U.S. on Chinese goods. This article explores the specific repercussions of these sanctions on China's hardware manufacturing industry and outlines strategic measures that companies should adopt to mitigate these effects. Impact on China's Hardware Manufacturing Industry Increased Production Costs The U.S. sanctions have resulted in higher export tariffs on Chinese hardware products, leading to increased production costs. This, in turn, affects the profit margins of Chinese manufacturers, making it more challenging to

In the realm of metal fabrication, the evolution of technology and techniques has continually paved the way for more efficient, precise, and cost-effective manufacturing processes. Among these advancements, progressive die stamping stands out as a significant leap forward, especially when compared to traditional single punch press operations. This article delves into the fundamental differences and advantages of progressive die stamping, highlighting why it is often the preferred choice for high-volume, complex metal part production.

Happy New Year! As the first day of 2024 unfolds, we at PROLANGH want to take a moment to extend our heartfelt New Year greetings to all of our valued clients and future partners.

In the realm of hardware manufacturing, the significance of quality control cannot be overstated. It is a pivotal aspect that not only reflects the integrity of a brand but also determines its success in a competitive market. At PROLANGH, our commitment to quality control is unwavering, and we have established a comprehensive system to ensure every product we manufacture meets the highest standards.