In the realm of hardware manufacturing, the significance of quality control cannot be overstated. It is a pivotal aspect that not only reflects the integrity of a brand but also determines its success in a competitive market. At PROLANGH, our commitment to quality control is unwavering, and we have established a comprehensive system to ensure every product we manufacture meets the highest standards.

Understanding the Importance of Quality Control

Quality control in hardware manufacturing involves a series of procedures aimed at ensuring that the products meet specific requirements and are free from defects. It's not just about adhering to industry standards but also about exceeding customer expectations. In a field where precision and reliability are paramount, the slightest deviation can have significant repercussions.

Our Approach to Quality Control

At PROLANGH, we approach quality control with a multi-layered strategy:

- Raw Material Inspection: Our process begins with the thorough inspection of raw materials. We understand that high-quality products can only be made from high-quality materials. Our team meticulously checks for consistency, composition, and integrity in all materials before they enter the production line.

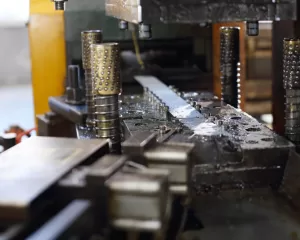

- In-Process Quality Checks: Quality control is an ongoing process throughout our manufacturing. Skilled technicians and engineers closely monitor each stage of production. Using both manual inspections and advanced technological tools, we ensure that each product aligns with our detailed design specifications.

- Final Product Testing: Before any product leaves our factory, it undergoes rigorous testing. These tests simulate real-world conditions to ensure that our hardware can withstand various stresses and usage scenarios.

- Continuous Improvement: We believe that quality control is an ever-evolving process. Feedback from the market, customer reviews, and internal assessments are continually fed back into our manufacturing process to enhance product quality.

Advanced Technology in Quality Control

Leveraging technology has been a game-changer in our quality control process. We employ state-of-the-art equipment such as 3D measurements and automated testing systems that provide high precision and consistency. Data analytics plays a crucial role in identifying patterns and potential areas of improvement.

Employee Training and Engagement

We recognize that our employees are the backbone of our quality control system. Regular training sessions are conducted to keep our team updated with the latest techniques and standards. Employee engagement in the quality control process is encouraged, as their firsthand experience and insights are invaluable.

Quality Control and Customer Satisfaction

Ultimately, the goal of our stringent quality control process is customer satisfaction. We strive to deliver products that not only meet but exceed customer expectations. This dedication to quality has not only earned us a loyal customer base but also positioned Prolangh as a trusted name in the hardware manufacturing industry.

Conclusion

In conclusion, at PROLANGH, quality control is more than a process; it's a culture. It's an intrinsic part of every step we take, from raw material selection to the final product delivery. We are committed to maintaining the highest standards of quality, ensuring that we continue to deliver excellence in every piece of hardware we manufacture.